Smart film PDLC, technology and functionality in transparency

The switchable PDLC film is the result of years of research and development, supported by modern production machinery and advanced quality control equipment Innoptec® uses state-of-the-art equipment to test performance and material combinations in advance, ensuring that each film is perfectly suited to your needs.

Over the years Innoptec® has developed two switchable PDLC film models. LPF intended for glass lamination, Click-LPF intended for self-adhesive application.

- Optimisation of space

- Diffuse and comfortable brightness: privacy without walls letting natural light through

- Shielding sunlight and reflections with low energy consumption for cooling in summer

PDLC TECHNOLOGY

IN THE SWITCHABLE FILM

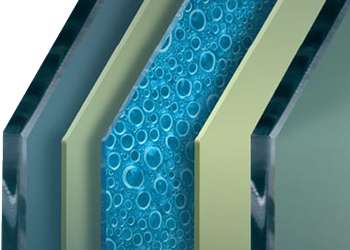

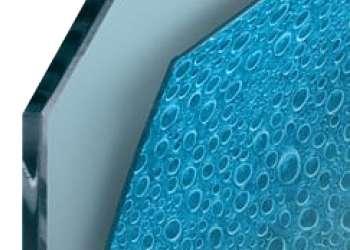

The switchable PDLC film acts as an electrically controllable filter, allowing you to adjust the transparency of the glass by applying an electric field according to your needs.

Film for glass lamination

LPF films are supplied cut to size and with electrical contacts applied, in sheets up to 2.0 metres wide and lengths that can even exceed 3 metres.

If the customer has sufficient know-how to enable independent application of the electrodes, Innoptec® can also supply LPF films in rolls of up to 30 metres in standard widths of 1.2 metres, 1.5 metres, 1.8 metres and 2.0 metres.

Achieving high final optical qualities, particularly for the product intended for glass lamination, requires equal attention to quality in all subsequent stages of switchable film production with PDLC technology.

Innoptec®, thanks to its 20 years of experience and its pilot laboratory equipment, is able to reproduce on an industrial pilot scale the procedures used by glass manufacturers and test adhesives, sealants, silicones and other materials chosen for the final installation phase.

The customer service provided by Innoptec® enables the entire supply chain to avoid many mistakes, as well as the resulting economic damage.

General features

Standard film widths: 1.200 mm, 1.525 mm, 1.800 mm, 2.000 mm.

Standard formats: Rectangular sheets obtained by laser cutting, according to required dimensions up to 30 linear metres (rolls).

Cutting and customisation: Possibility of cutting curved shapes, pre-cutting the strip for the electrodes, applying the electrodes to positions requested by the customer from a range of standard combinations.

Power supply: Innoptec® film is powered at 45 or 60Vac/50Hz by transformer. Different solutions are available for powering the LPF film (remote control - dimmer - etc.).

Colours: FILM is available in ice and pastel grey. Grey is available on request.

Technical Information

Innoptec® is standing by to provide the most appropriate solutions to your requirements, taking into account the effectiveness and safety of the installation.

| OFF status (opaque) | |

| Total Transmitted Light | 55% ( +/-5%) |

| Direct transmitted light (1st collection angle) | < 1 % |

| Status ON (transparent) | |

| Total transmission | 90% |

| Haze | 3% |

| Angled Haze (45°) | 13% |

| Power requirement | 3-5 W/m2 |

| Response times | < 0,1 sec. |

Download

Self-adhesive film

Switchable Click-LPF film by Innoptec® self-adhesive

Not only on glass, but also on transparent sheets such as polycarbonate, polyacrylate, PET and polystyrene

The film consists of an electro-optical liquid crystal film that can be dry-applied to glass or other transparent surfaces. The Click-LPF film is removable without leaving any residue on surfaces.

This is a product whose application process is simpler, but requires the right dexterity. It is suitable for even small applications.

General features

Standard film widths: 1.2 metres, 1.5 metres, 1.8 metres (grey version up to 1.5 metres).

Standard formats: Rectangular sheets obtained by laser cutting, according to the dimensions requested by the customer. Innoptec® can also supply formats other than rectangular, the quotation for these formats is to be evaluated on a case-by-case basis.

Cutting and customisation: The possibility of cutting curved shapes, pre-cutting the electrode strip, applying electrodes to positions required by the customer from a range of standard combinations.

Power supply: Click-LPF film is supplied at 45 or 60Vac/50Hz by a transformer. Different solutions are available for the power supply of the LPF film (remote control - dimmer - etc.).

Colours: FILM is available in ice and pastel grey. Grey is available on request.

Technical Information

Innoptec® is standing by to provide the most appropriate solutions for the customer's needs, naturally taking into account the effectiveness and safety of the installation.

| OFF status (opaque) | |

| Total Transmitted Light | 55% ( +/-5%) |

| Direct transmitted light (1st collection angle) | < 1 % |

| Status ON (transparent) | |

| Total transmission | 90% |

| Haze | 3% |

| Angled Haze (45°) | 13% |

| Power requirement | 3-5 W/m2 |

| Response times | < 0,1 sec. |

Download

THE SUPPLY PROGRAMME

The sheets are cut by a special computerised machine that receives

the shape drawing (Autocad software) directly via the Internet, a service

appreciated by architects and designers as well as glass technicians.

R&D INNOPTEC®

Switchable PDLC films are innovative materials that add functionality to glass

and other transparent surfaces: new applications for the management of light

and space, capable of bringing glass from the high transparency of the 'on'

state to the bright and versatile translucence of the 'off' state.

INNOPTEC® PDLC FILM:

THE CONTROL SYSTEM

![]()

Manual ON/OFF button

The manual ON/OFF button can also be placed in a room other than the glass provided that it is within 20 metres.

![]()

Remote control

With dedicated application.

![]()

Home automation

With compatible home automation system.

INSIGHTS

Why choose Innoptec® technology? Everything that makes intelligent glass special, from privacy to architectural design.

ADVANTAGES

Smart glass not only as a new architectural concept.

Are you an entrepreneur or a glass technician?

Enter your reserved area and discover how Innoptec® can make your product intelligent >